News

R&D: Increased efficiency economizers biomass boilers

Focus of this project was to make production of renewable heat and power from biomass less expensive.

Business case

The overall efficiency of biomass – Combined Heat and Power (CHP) systems is largely determined by the temperature of the flue gas leaving the chimney stacks. The more the flue gas can be cooled, the higher the overall efficiency of the system.

In practice the cooling of flue gas is limited to 130 – 170 degrees Celsius. Suppliers of economizers want to avoid condensation of Sulphur on the walls of the unit. Due to the formation of this acidic condensate, these heat exchangers will have accelerated corrosion. The corrosion related problems that occur in practice are complex. Besides Sulphur also other toxic and potentially acidic substances play an important role, and knowledge of these interactions are mostly limited. Engineers and suppliers of Economizers usually opt for safe and proven numbers and guidelines intended for design of coal fired boilers.

The standard solution to cool the flue gas is generally the application of a condenser that brings large quantities of water into contact with flue gases. Recovery of heat will be gained on a relatively low temperature level (e.g. 40°C). To give this recovered heat a useful application is unfortunately mainly not possible.

Owners of biomass-Combined Heat and Power (CHP) plants want to save on production costs and want to make good use of the recovered heat from flue gases as much as possible.

The aim of the project

The primary objective of this project was to increase the overall efficiency of biomass boilers. By reduction of heat leaving the chimney, and to regenerate heat on a higher temperature level above the performance of standard flue gas condenser units. In general, heat over 70°C is valuable an can be reused for another application.

Development of an Economizer(heat exchanger) which is more resistant to corrosion at low temperatures has major benefits. The flue gas temperature can be cooled to below the water vapor dew point, and heat on a valuable temperature level can be recovered. As a result the application of this heat to, for instance greenhouses, is relatively easy.

Increasing the efficiency leads to savings on fuel costs and cheaper production of sustainable energy (heat and power) from Biomass.

Short description of the project

Extensive measurements of flue gases from a biomass fired boiler of a CHP plant were carried out to make a new design of a economizer which can be used at lower temperature levels. This means that flue gases of a biomass plant can be cooled to a lower temperature level than usually.

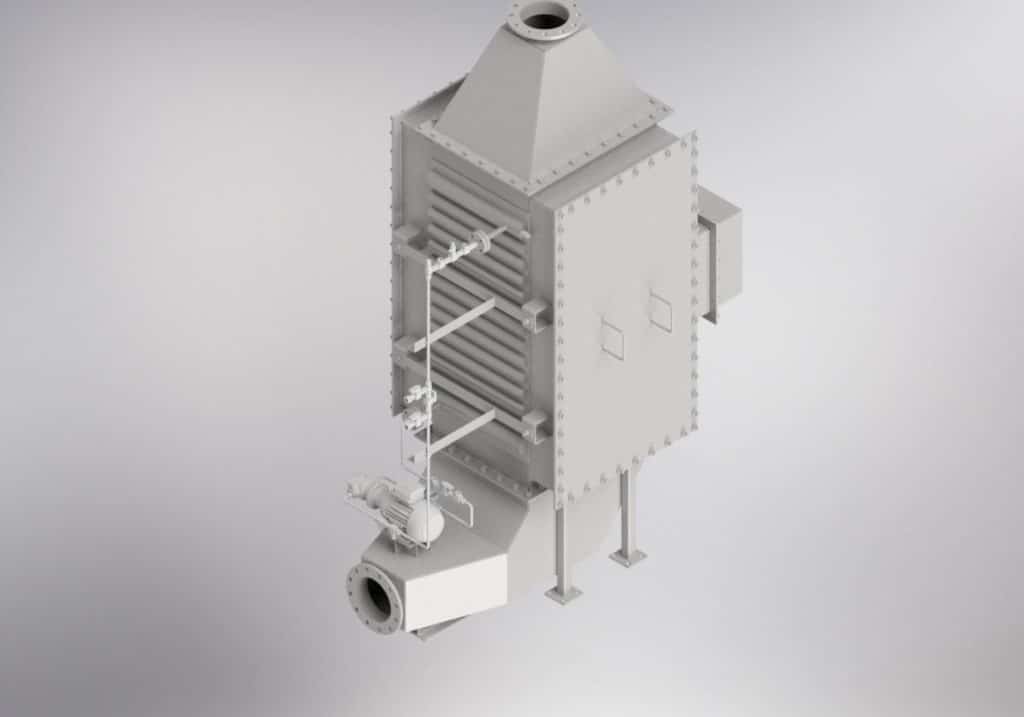

In collaboration with Dutch companies ECN part of TNO and TBM R&D in this project, was Geurts responsible for the engineering and fabrication of the heat exchanger. This economizer can be used for deep cooling of flue gases. The unit can be equipped with online fouling cleaning devices to maintain optimal thermal conductivity. This new development in our product range of Economizers will be long term tested for lasting quality. Testing will be done in a biomass plant of TBM Europe B.V. The Dutch Organization ECN part of TNO is an Energy Research Centre of the Netherlands (ECN part of TNO), one of the largest energy research institute in Europe and holds a strong international position. ECN part of TNO is responsible for project coordination and all measurements and analyses on the flue gas side of the system.

Result in boiler efficiency

The result of this project is the design of an economizer which can be employed on lower flue gas temperatures. The ambition with the design is to apply the system using a feed water less than 65°C. Long term testing (> 500 hours) in realistic conditions on limited scale (> 50 kWth).

Each reduction of 15°C in the flue gas leaving the chimney, results in 1% overall efficiency increase of the boiler system. This corresponds to savings on fuel costs of an equal percentage. The aim in the final results is a reduction of the flue gas temperature leaving the chimney from 130°C to at least 85°C. This means an efficiency gain and increase of at least 3%. This is a conservative approach.

EN

EN NL

NL FR

FR SK

SK